Services

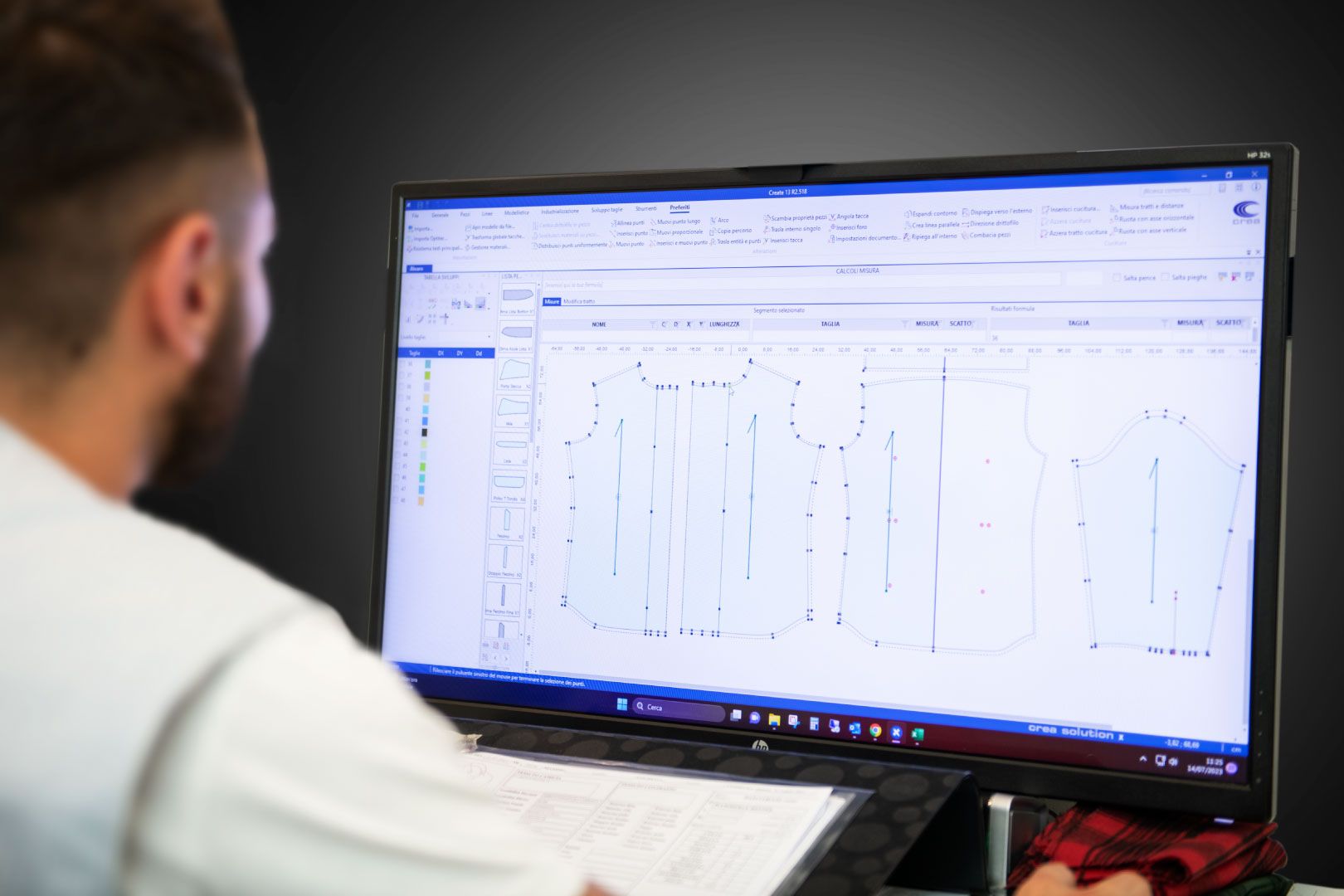

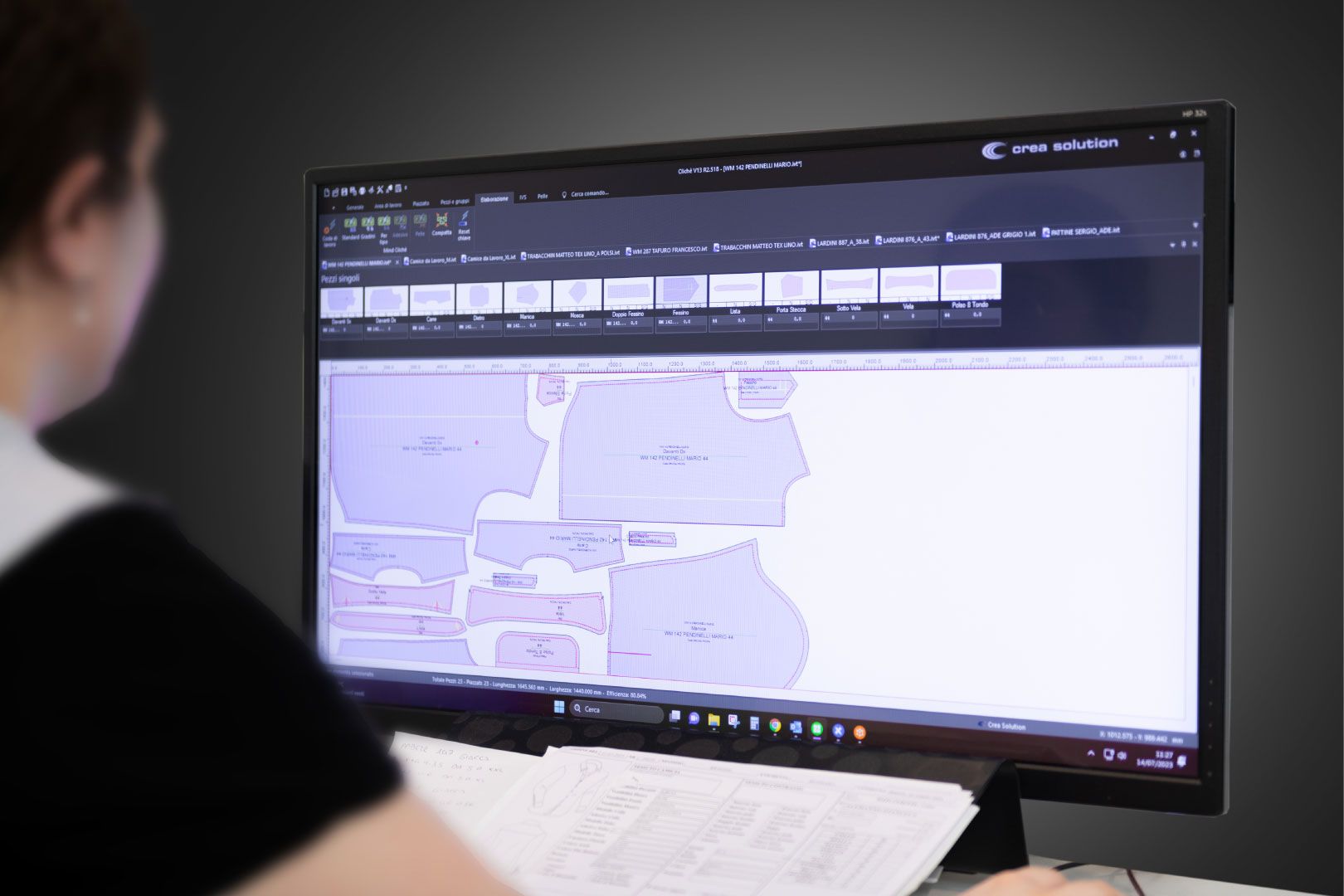

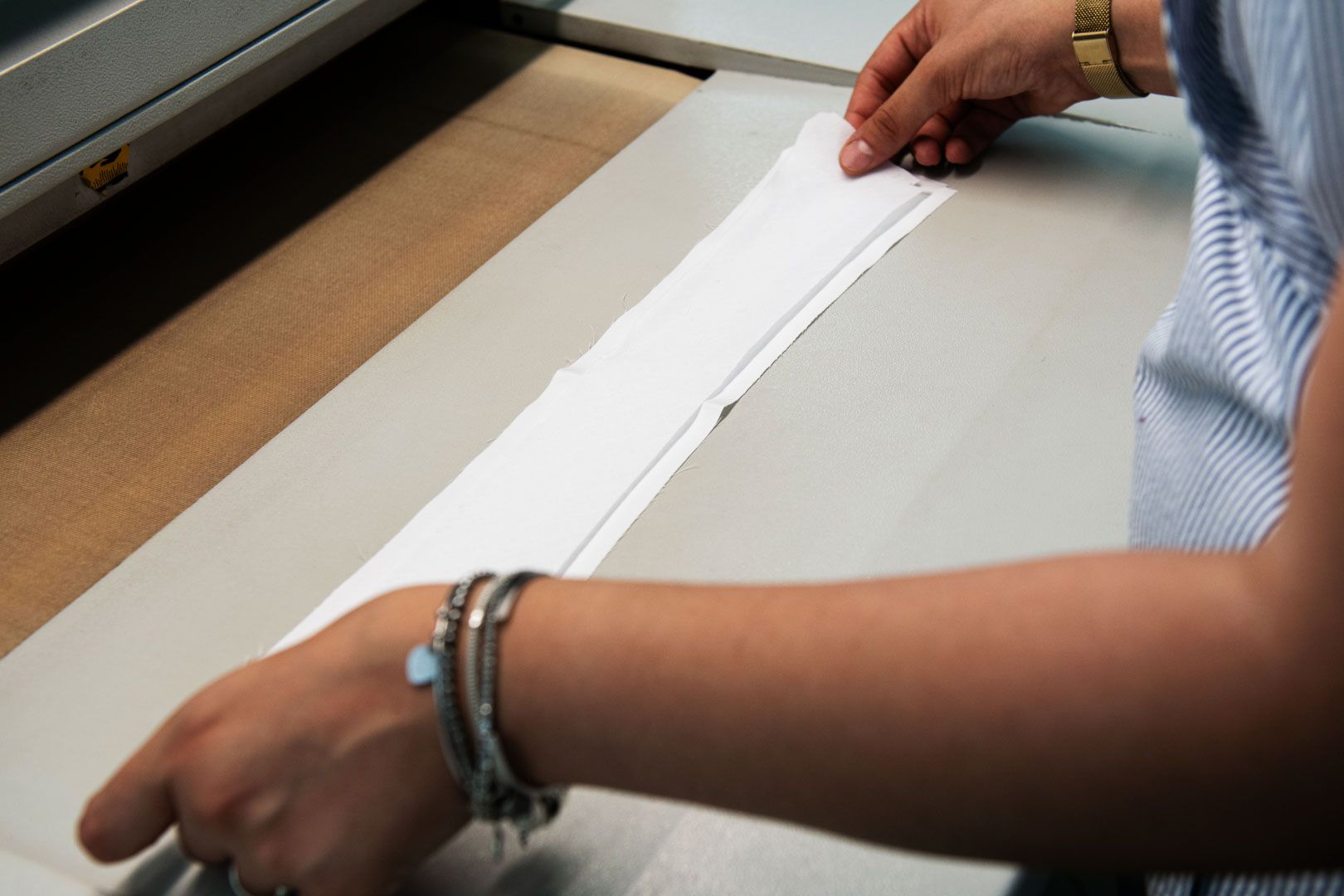

Pattern making

Where the shirt takes shape: pattern making excellence

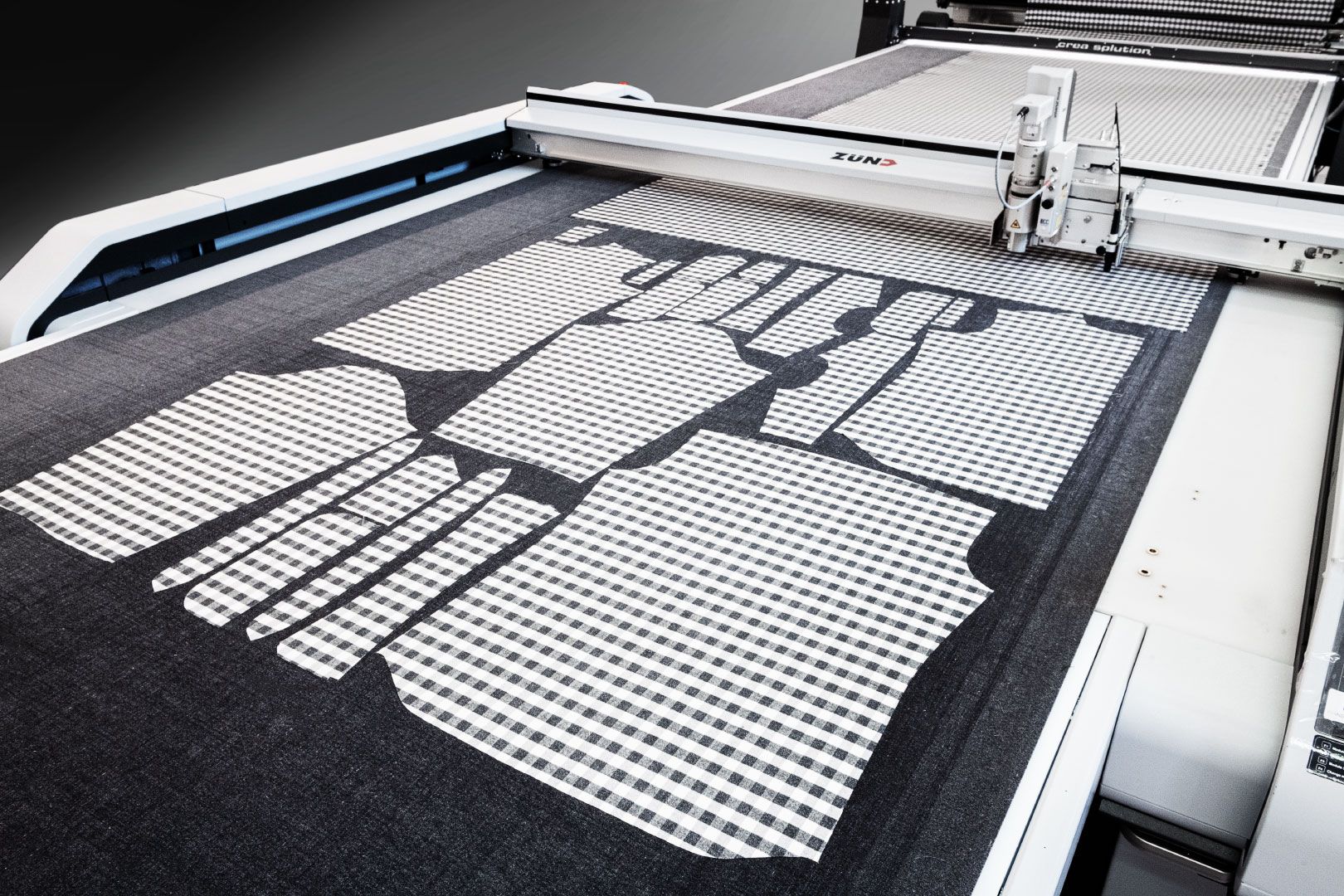

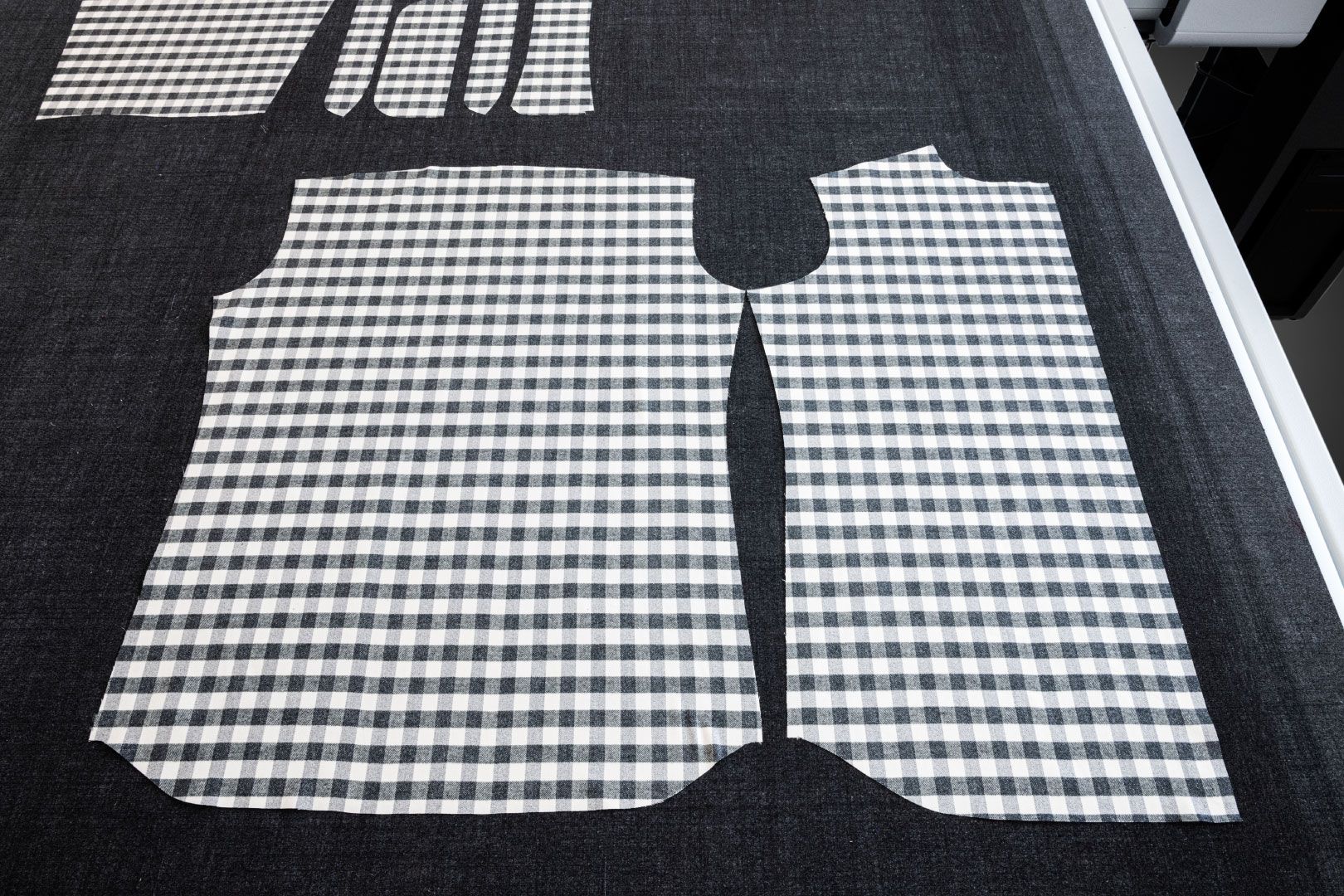

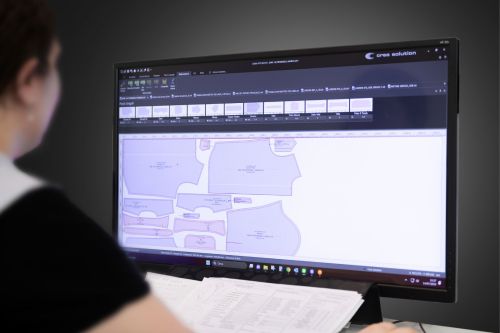

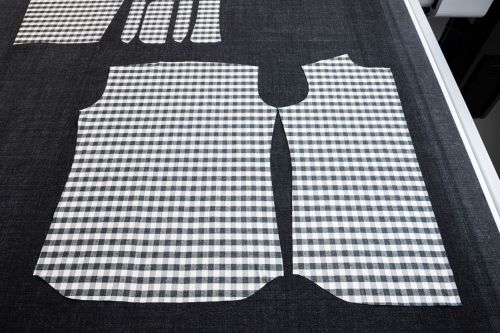

In our pattern making department, every shirt is the result of a meticulous process that combines creativity, technical expertise, and innovation. It all starts with the creation or importation of patterns, which are handled with the utmost care and precision to ensure the perfect balance between fit, style, and functionality.Once the first prototype has been created, the team steps in to develop all sizes with sartorial attention, ensuring consistency, comfort, and quality in every variation. Before the cutting phase, we optimize every detail: thanks to automatic placement and artificial vision systems, we achieve maximum efficiency in fabric consumption—whether plain, striped, checked, with panels, or logos—reducing waste and ensuring a flawless result.

Our modeling process is the first step towards a perfect shirt: designed, studied, and refined to fit every person perfectly.

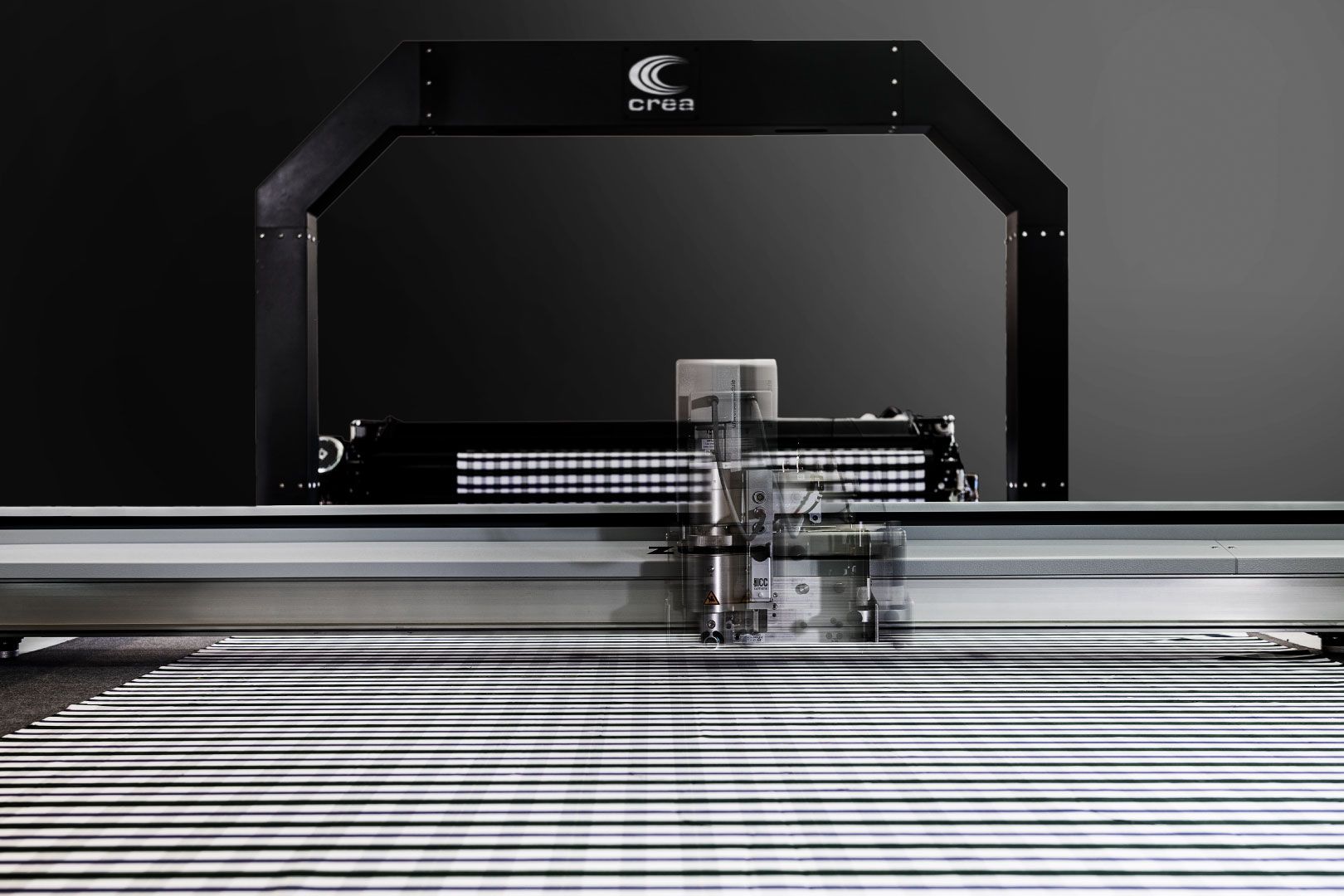

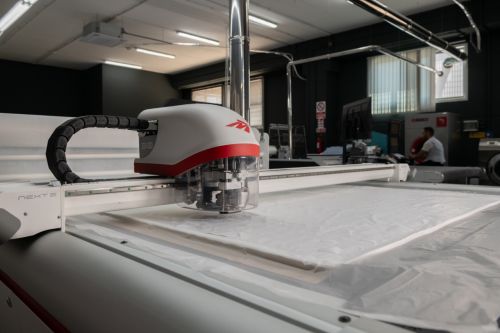

Single Sheet Cutting

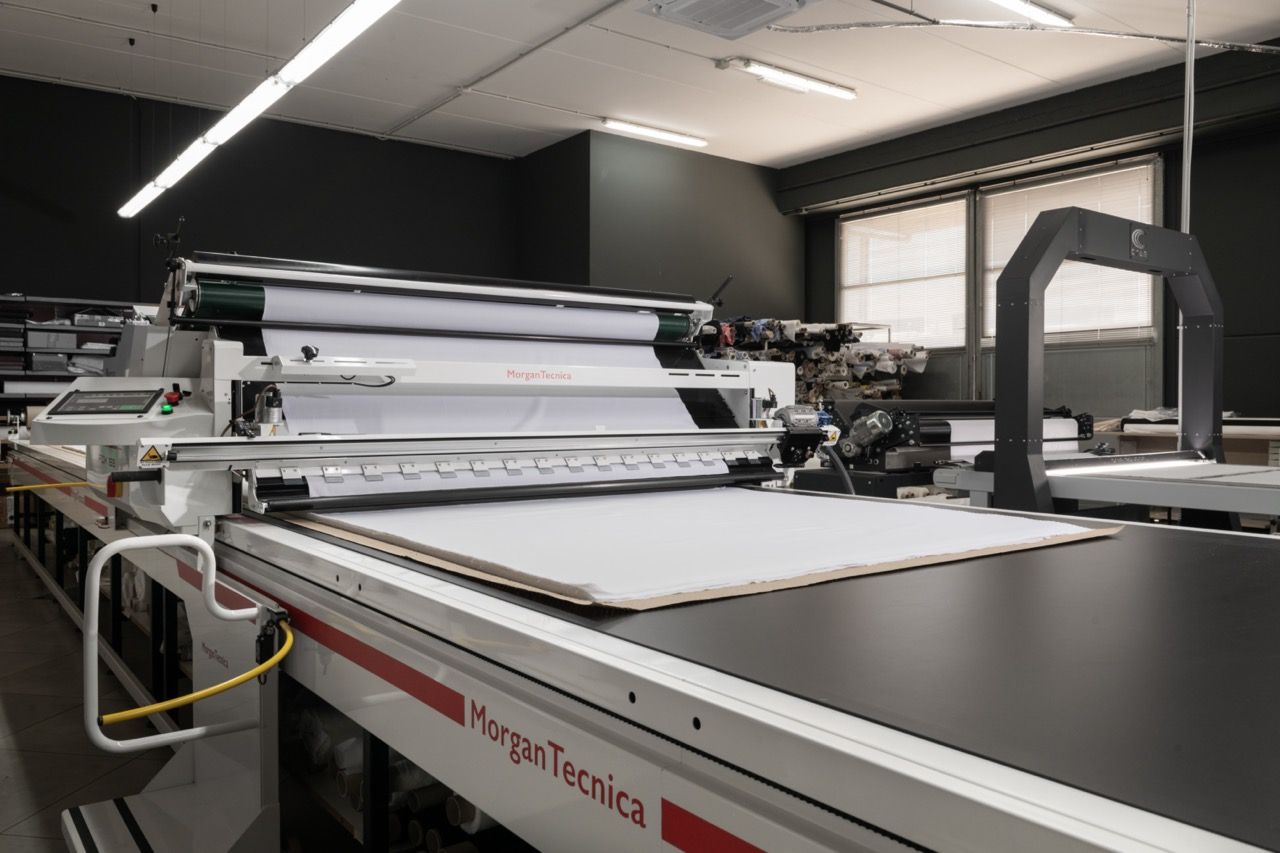

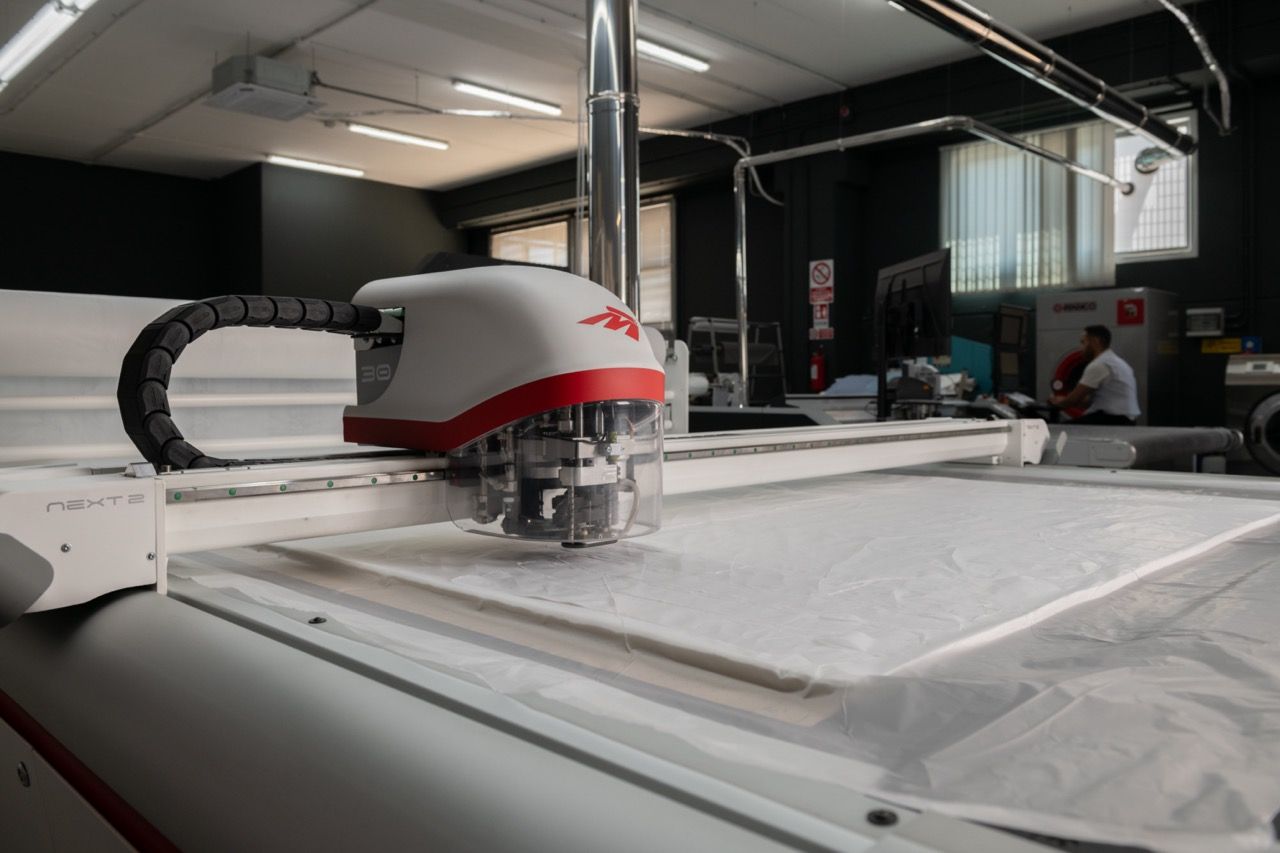

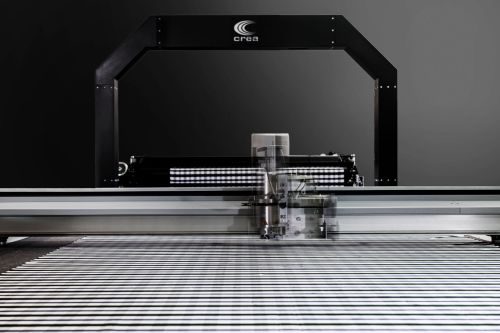

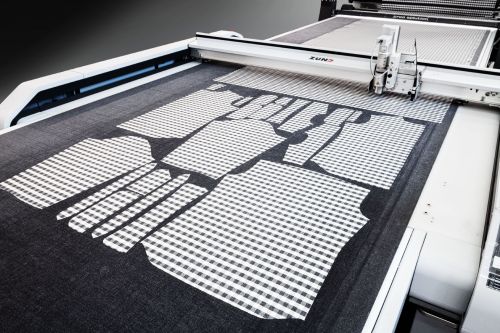

Cutting-edge technology at the service of precision: cutting by Sarty In our production department, the cutting phase is the beating heart of innovation. Thanks to Crea Solution's IRIS system with artificial intelligence, we digitize every fabric with millimeter precision, defining its parameters even in the presence of complex patterns such as stripes, checks, panels, or logos. Our defect control software intervenes promptly to identify and correct any imperfections.Cutting is performed using single-sheet technology on a non-slip suction mat, eliminating waste and maximizing process efficiency. We are proud to combine sartorial accuracy with industrial efficiency, while promoting more responsible and sustainable production.

Multi-Layer Cutting

Sewing

Washing

Embroidery

Quality

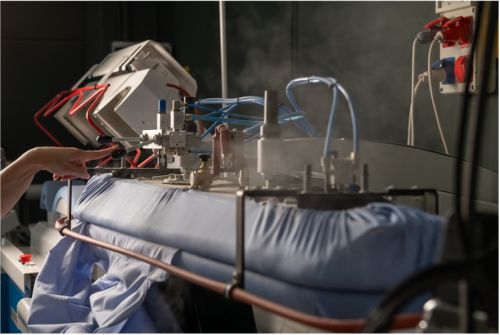

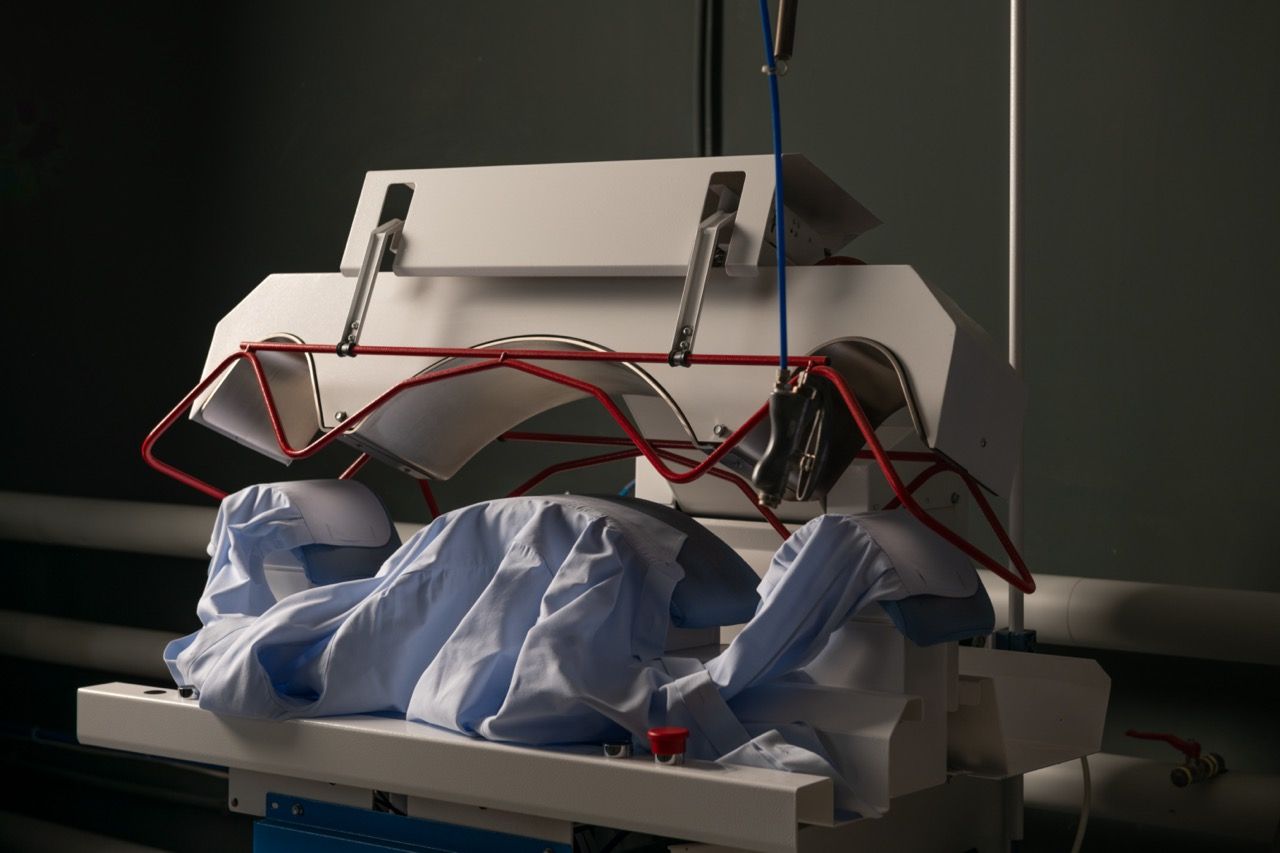

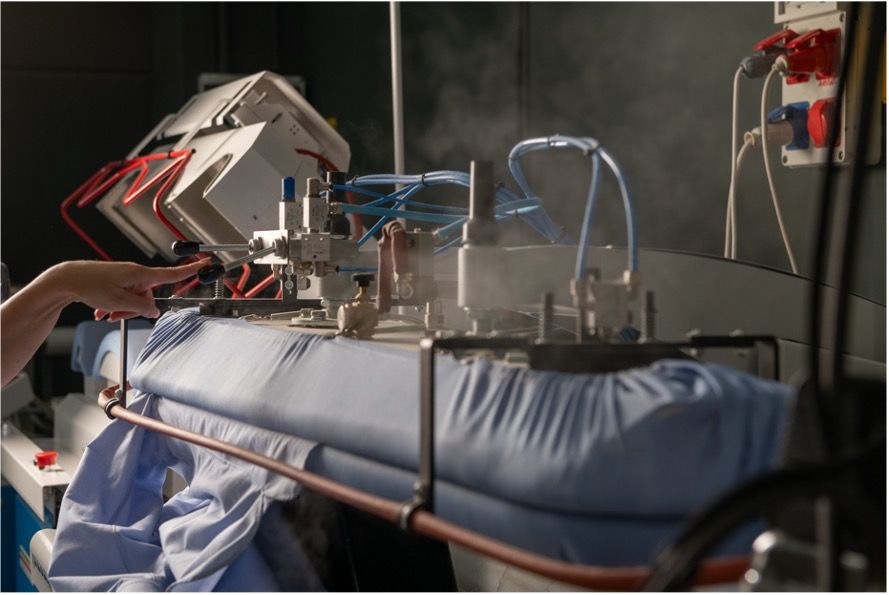

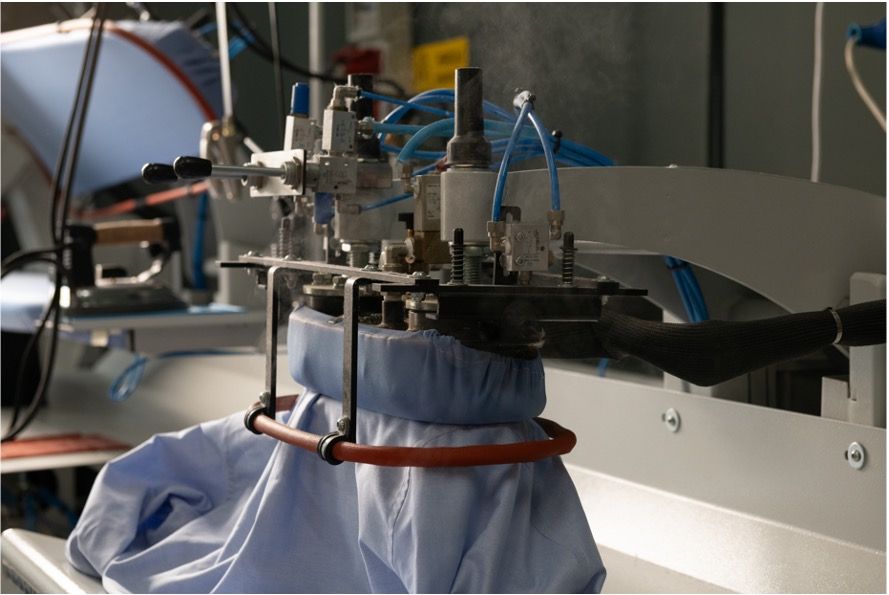

Ironing